One of the primary factors in determining your approach to packaging line automation is to take a look at your existing warehouse environment. Packaging environments differ based on many variables such as the type of business, warehouse layout, and the number and sizes of products to be shipped. As examples, a manufacturing facility may produce products in batches, while an e-commerce fulfillment center may require shipments of single- and multi-item orders. Other facilities may require packaging of small or similar-sized items, while others may have large, heavy and/or odd-shaped products to ship. Each would benefit from automation, but each requires a different automatic packaging solution to achieve the best results.

Since packaging processes can be carried out in a number of different ways based on operational requirements, the best way to optimize your warehouse is to fully assess and understand your existing workflow. With the assistance of an Automated Packaging Professional, you can look at your packaging line holistically to design a customizable solution that matches your product flow, from shelves to shipping.

Although no two packaging environments are alike, every packaging process includes some form of data integration, product transport, carton production, product protection, carton erect, carton packing, sealing, marking, sortation, and business intelligence. See our previous blog post to learn more about this. On Demand Packaging® solutions can enhance processes and flow by integrating with one or more of these 10 features, depending on the workflow environment. The following examples illustrate different packaging environments and the benefits of a customized Packsize system in each.

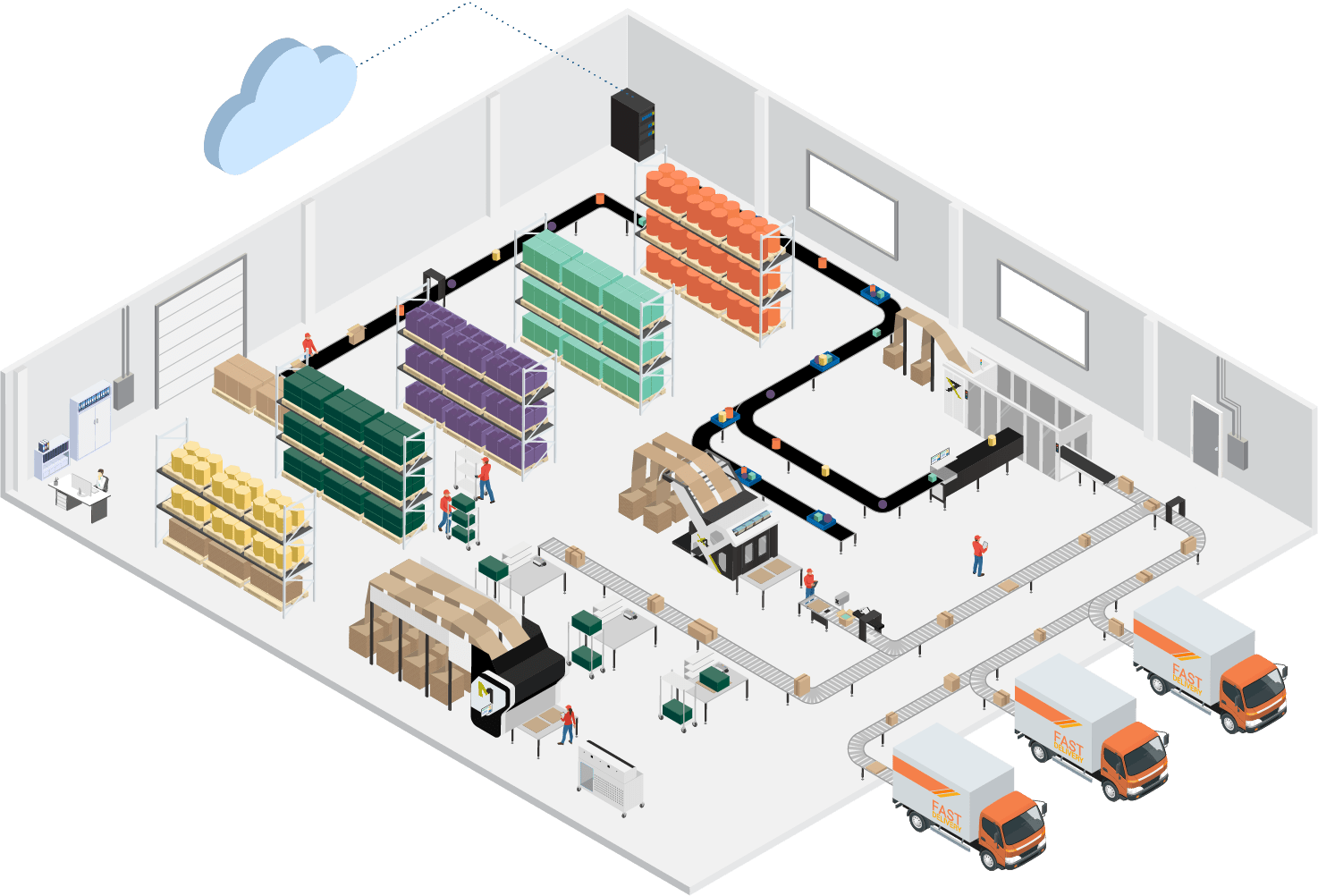

“Box Last” is a highly-automated packaging flow designed for manufacturing or distribution facilities that need to pick and package single- or multi-item orders. While utilizing three Packsize machine systems and an integrated software platform, this packaging process produces a right-sized box-last, for the right product, in the right sequence, every time. All 10 features of the packaging process are integrated in this solution.

This process employs conveyance automation (and also works for non-conveyable or oversized items, from the picking of products). Each product is scanned for dimensional data and placed on warehouse racking. Sortation occurs at the scanner placed on the conveyor before the three shipping trucks.

In this example, the M1 packages large, non-conveyable orders, the X4 handles medium conveyable single- or multi-item orders, and the X7 packages smaller, conveyable, single- or multi-item orders.

A large outdoor retailer has taken big steps to fine-tune packaging in its distribution centers by employing the Right-sized Packaging on Demand “box last” process, integrating several automated, small-footprint packaging machines to produce custom boxes for every order. Prior to utilizing this process, the company stocked an inventory of boxes, in varying sizes, at several pack stations, wasting time, money, and efficiency. Right-sized packaging lowered their dimensional charges, reduced the cost of materials and labor, all while increasing throughput.

“Box First” is another highly-automated packaging solution that pairs boxes automatically with an order ready to be packed. Each product is scanned for dimensional data and placed on warehouse racking. Items are packed in the box as the box is conveyed through the warehouse racking. Sortation occurs at the scanner placed on the conveyor before the three shipping trucks.

Customize your On Demand Packaging solution to enhance processes and flow

Leading cake decoration supplier DecoPack utilizes a box-first On Demand Packaging solution after realizing the need to increase automation to support higher shipping volumes to its customers. Prior to automating, the company would pick orders into a tote, transport the tote to packing stations and then take the items out to pack into a pre-selected carton chosen from a large box inventory. This process required several workers in pick lines and large amounts of corrugated and void fill. Right-sized packaging provided the automation solution they needed, while reducing time, touch, and travel in their packaging and shipping process.

In a manufacturing environment products may be produced in batches (the same item is produced for a certain production run), or by a purchase order, down to a single unit at a time. Products may be large, oddly-shaped, or heavy. This process illustrates a Packsize machine accommodating either production environment. Depending on the variation of products produced, packaging needs, takt time required, and other variables, On Demand Packaging solutions can be customized to improve throughput and reduce costs.

For customers seeking higher automation for large, odd-shaped, and/or heavy products

Forward-thinking furniture manufacturer Legacy Cabinets sought to reduce empty space and improve protection when shipping its cabinetry. However, the initial attempt at right-sizing required a substantially large box inventory. This required significant time, costs, and management of 500 box SKUs. Legacy Cabinet’s inventory now consists of only five different sizes of z-Fold®.

This packaging solution features less automation and integration than the other manufacturing environment references. Products are transported to Packsize machines for custom box production then packed and shipped by an employee. This process can be integrated with packaging software to scan a product for dimensional data as it is unpackaged and placed on warehouse racking.

Can be customized for any workflow

For more than 20 years, Central Carolina Products relied on a traditional store-and-retrieve box inventory system to ship custom auto parts and other injection-molded products. Waiting for box vendor quotes and orders added several days to its lead time. After incorporating an On Demand Packaging solution, they can now create 100 custom boxes for 100 different parts at no extra cost and with no additional lead time.

In batch production, an automated packaging machine creates batches of boxes, eliminating the need for a box inventory. In the illustration below, it is assumed that the production run is generated by an integrated software system, which means that this is higher on the integration scale, even though the packaging process flow is lower on the automation scale.

Eliminate the dependency on box vendors for stock boxes and custom orders

Packaging is typically the final part of any manufacturing or order fulfillment process, and often, the last to be optimized. The process solutions above emphasize the role a packaging line plays in achieving business objectives, increased throughput, reduced labor, and cost savings. Just as no two warehouse environments are alike, automation is not a one-size-fits-all remedy, but rather a customizable and flexible solution designed to streamline warehouse operations, increase sustainability, reduce costs, and increase customer satisfaction.

Contactez-nous dès aujourd'hui pour une analyse personnalisée de votre processus d'expédition.